Specially developed sealing and insulating elements for transformer devices, in the form of O-rings, sheets, profiles, flat and profiled gaskets, made from certified, specially developed high-quality elastomers NBR, HNBR, FVMQ, FKM, and specially designed laminated materials: HgW (rigid glass laminate). Our products meet the strictest transformer industry standards, ensuring long-lasting and reliable operation of your devices.

OUR RANGE OF INSULATING PRODUCTS FOR TRANSFORMERS

We take pride in a wide range of sealing and insulating elements tailored to the specific needs of the transformer industry. Our offer includes:

-

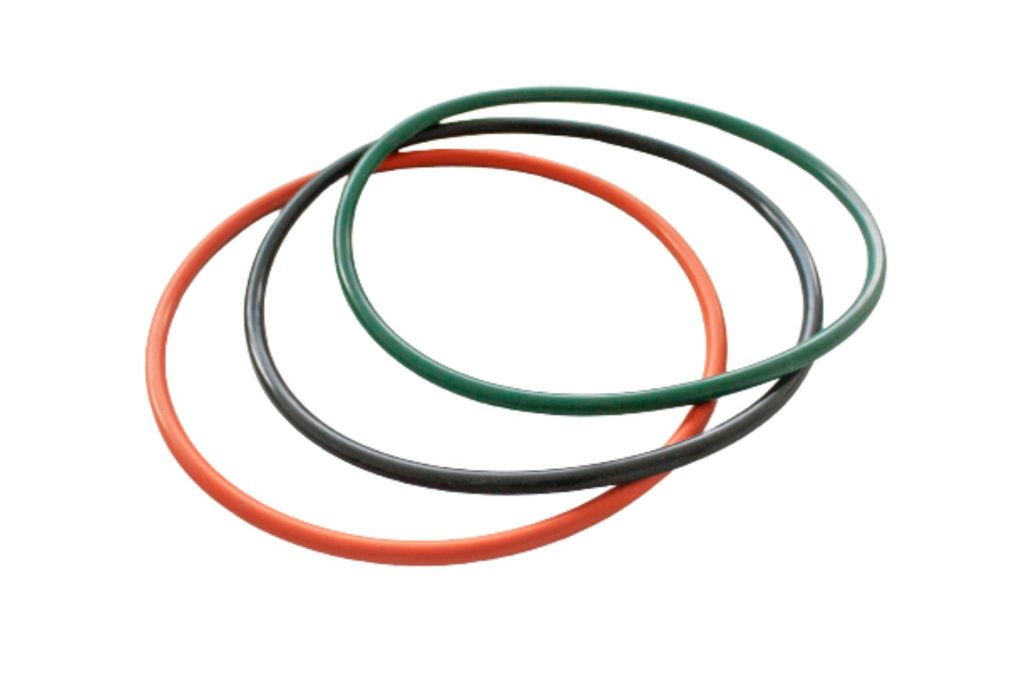

- O-rings: Classic sealing elements that provide durable and secure sealing.

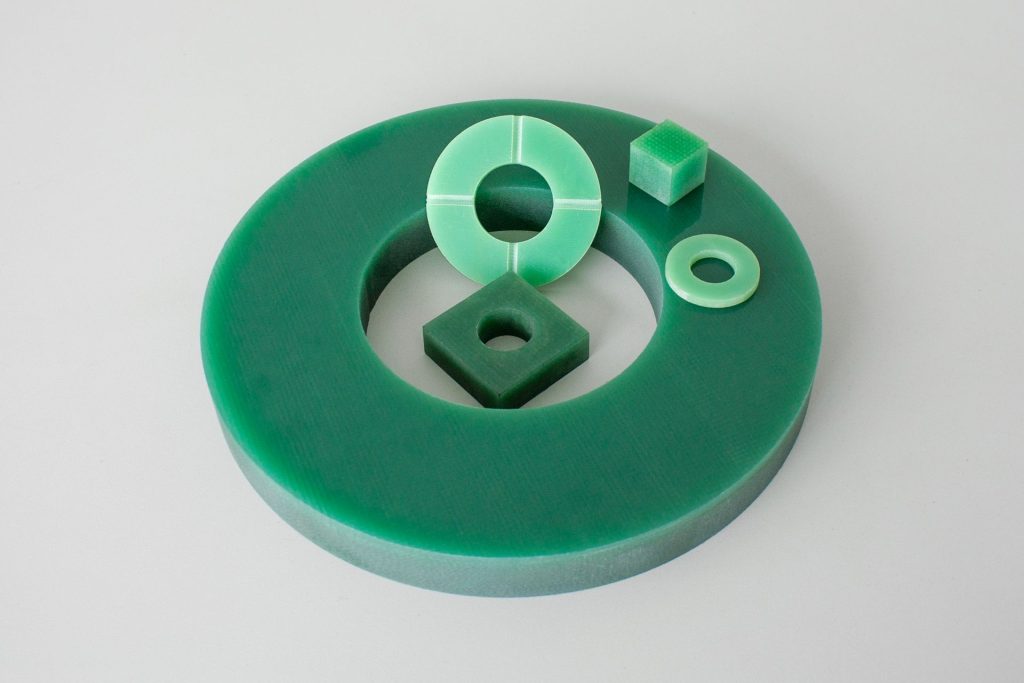

- Insulating sheets: Suitable for various applications, providing high resistance to temperature and pressure, with specially developed elastomer sheets for magnetic shields also offering excellent noise and vibration insulation.

- Insulating and sealing profiles: Adaptable and flexible products ensuring precise and secure sealing under various conditions.

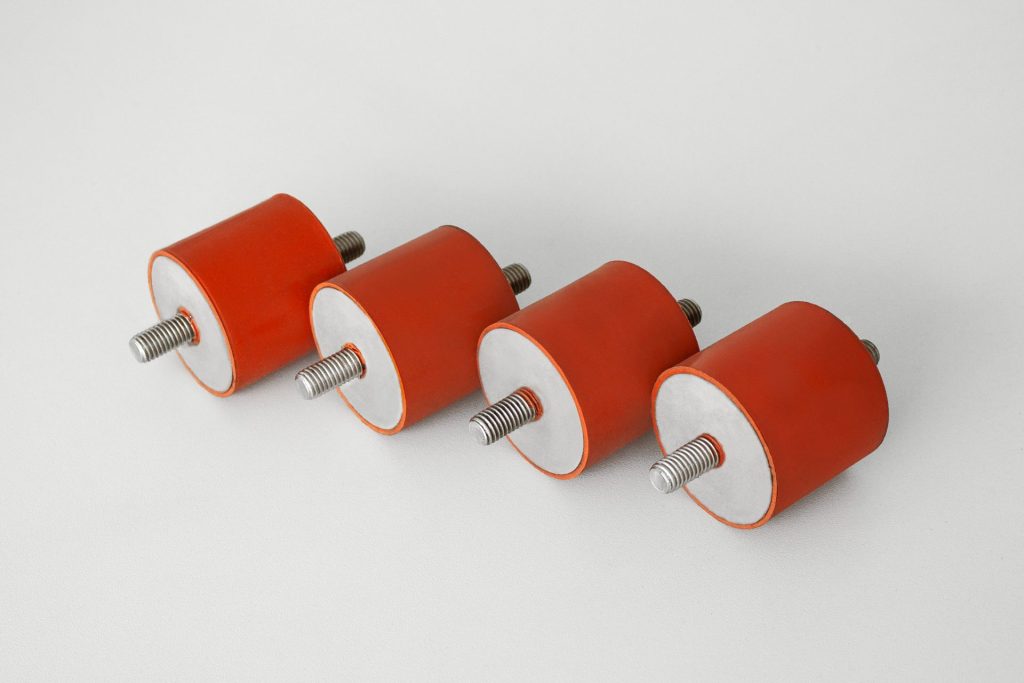

- Flat and profiled gaskets: Provide durable and secure sealing even under the most demanding conditions of the transformer industry.

All our products are made from specially developed high-quality materials:

- NBR (Nitrile Butadiene): Resistant to oils, fuels, greases, gasoline, and other aliphatic hydrocarbons. Has good electrical insulation properties, solid tear strength, abrasion resistance, and flexibility in a temperature range from -40 ̊C to +130 ̊C. Characteristic color: black.

- HNBR (Hydrogenated Nitrile Butadiene): Resistant to oils, greases, fuels, coolants, acids and alkalis, ozone, and UV radiation. Maintains elasticity and strength even at extreme temperatures from -30 ̊C to +150 ̊C, temporarily up to +175 ̊C. Characteristic color: black.

- FVMQ (Fluorosilicone Rubber): Resistant to fuels, oils, solvents including aromatic and aliphatic hydrocarbons, esters, alcohols, ozone, UV radiation, and oxidation. Maintains elasticity and strength over a temperature range from -60 ̊C to +180 ̊C, with special formulations down to -65 ̊C and up to +230 ̊C. Characteristic colors: brick red and light blue.

- FKM (Fluorocarbon Elastomer): Resistant to strong acids and alkalis, fuels, oils, solvents, alcohols, ketones, and other aggressive chemicals, ozone, and UV radiation. Maintains elasticity and strength at temperatures from -30 ̊C to +240 ̊C, with special formulations up to +280 ̊C. Characteristic colors: black and olive green.

- HgW (Rigid Glass Laminate): Material based on glass fibers impregnated with thermoset resins, resistant to oils and lubricants, solvents, and a wide range of chemicals. Exhibits excellent mechanical properties (bending, pressure, and impact resistance) and excellent dielectric properties at temperatures from -40 ̊C to +150 ̊C. Characteristic colors: green and beige.

- . Characteristic colors: green, beige.

WHY CHOOSE OUR INSULATING PRODUCTS FOR TRANSFORMERS?

- High quality and reliability: Our products are designed and manufactured according to the strictest industry standards, ensuring longevity and secure sealing of your transformer devices.

- Expertise and experience: Our team of experts with extensive experience in designing and manufacturing sealing and insulating elements for the transformer industry offers top service and support, helping you choose the best products for your needs.

- Global partners: Trust from leading world companies such as Siemens Energy, Končar Power Transformers, Kolektor Etra, Končar D&ST, SGB, Lemi Trafo, etc., confirms the high quality of our products.

- Customized solutions: Each product is tailored to the specific requirements of our clients, ensuring solutions that perfectly meet your needs.

INNOVATIVE TECHNOLOGIES AND QUALITY CONTROL

We use advanced manufacturing technologies with special attention to quality control to ensure that all our products meet the highest transformer industry standards.

Contact Us

If you have any questions or want to learn more about our transformer products, please contact us. Our expert team is available to help you find the ideal solution for your specific needs.

Order now and ensure long-term reliable sealing and insulation for your transformers!