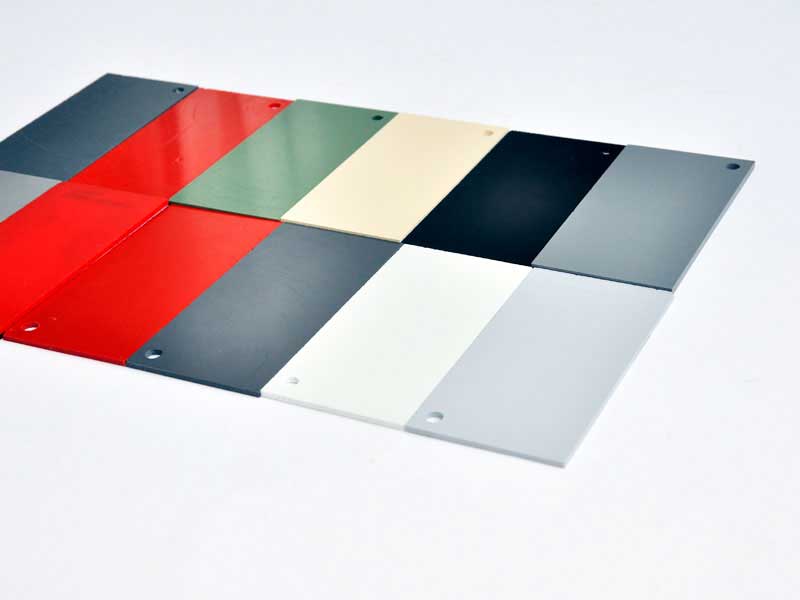

Cetidur

Cetidur is a rigid PVC distinguished by high fire resistance and excellent adhesive properties, making it an ideal solution for industrial applications that require high mechanical performance and fire resistance.

Material Characteristics:

-

- High fire resistance: Cetidur is highly resistant to high temperatures and flames, making it suitable for use in demanding environments where fire resistance is essential.

-

- Self-extinguishing: The material self-extinguishes once the fire source is removed, adding extra safety in industrial conditions.

-

- Adhesive properties: Cetidur has excellent adhesive qualities, making it suitable for bonding and welding with other materials. It is also an excellent base for printing.

-

- High mechanical loads: This plastic can withstand high mechanical stresses without significant deformation, making it suitable for industrial applications requiring structural materials.

-

- Low deformation: The material shows minimal distortion under mechanical loads, making it stable and durable.

-

- Can absorb up to 2% moisture at 50% humidity, an important property for applications exposed to high moisture conditions.

Dimensions and Shape:

-

- Dimensions: According to customer request

Technical Standards:

Cetidur complies with the DIN EN ISO 1043-1 standard for PVC-U and polyvinyl chloride (PVC), meaning it is tested for standard industrial applications.

Advantages of Using Cetidur:

-

- Demanding industrial applications where high temperature conditions and fire resistance are critical.

-

- Adaptability for welding, printing, and bonding allows flexibility in production and assembly processes.

-

- Exceptional mechanical stability enables use in products exposed to heavy loads and harsh conditions.

-

- Minimal deformation under load extends the product’s lifespan.

Applications of Cetidur:

- Flexible assembly and manufacturing of components with welding and bonding

-

- Manufacturing of electrical and electronic components

-

- Automotive industry (for components that must withstand high temperatures and mechanical loads)

-

- Industrial parts requiring fire resistance and durability under harsh conditions

-

- Packaging and processing where excellent stability at high temperatures is needed

- Flexible assembly and manufacturing of components with welding and bonding