Technical plastics and thermoplastics

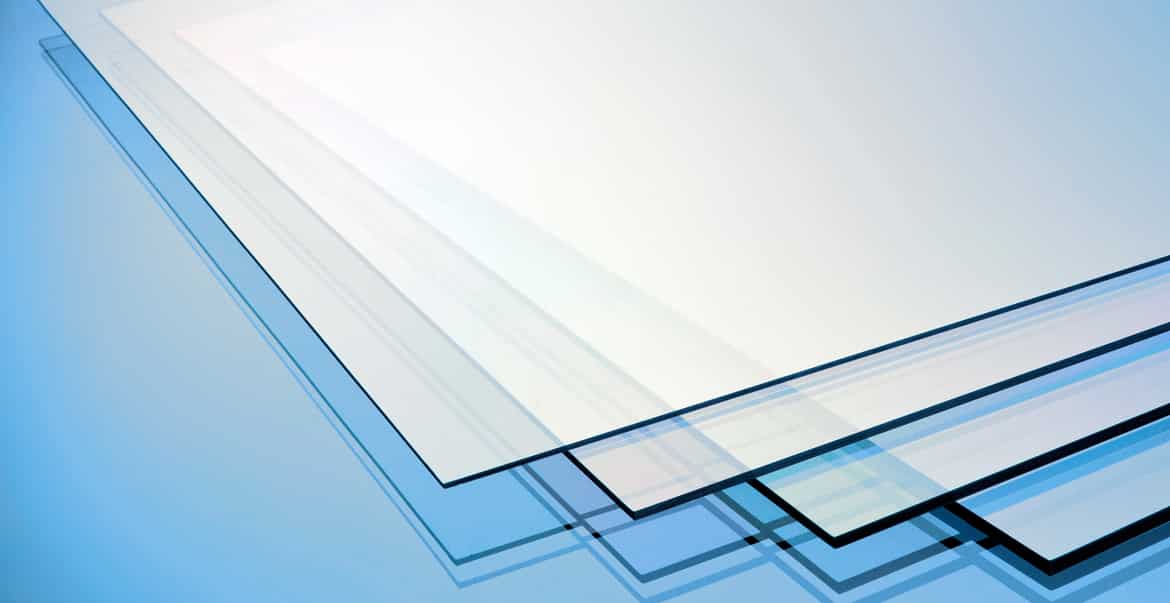

Technical plastics and thermoplastics are widely used in various industries due to their unique characteristics and cost-effectiveness. These materials are often considered as alternatives to traditional materials such as wood, metal, ceramics, and glass, as they offer superior properties and are suitable for a wide range of applications.

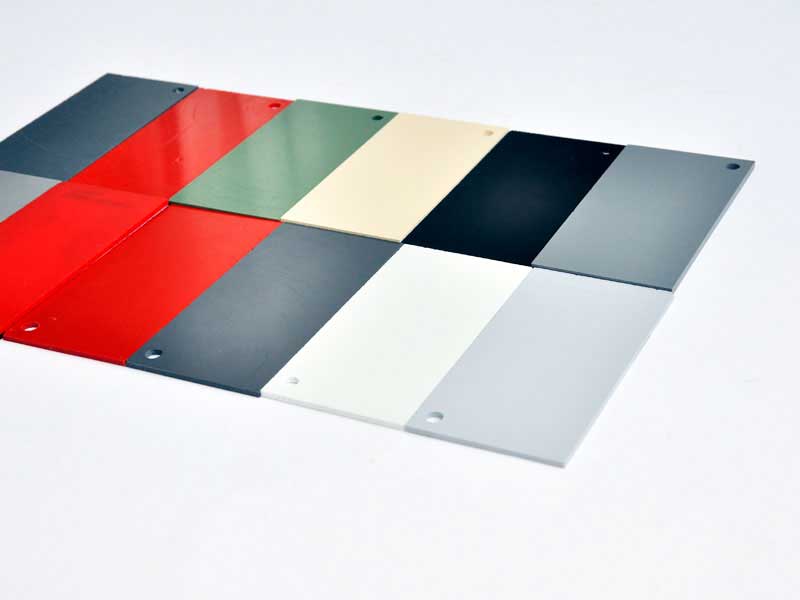

Standard plastics, also known as commodity plastics, are widely used due to their low cost and good mechanical properties. These materials are often used in packaging, consumer goods, and building materials. Some examples of standard plastics include polyethylene (PE), polypropylene (PP), and polystyrene (PS).

Engineering plastics are high-performance materials that offer excellent mechanical, thermal, and chemical properties. These materials are often used in applications that require high strength, stiffness, and resistance to heat and chemicals. Some examples of engineering plastics include polyamide (PA), polyacetal (POM), and polyphenylene oxide (PPO).

Plastics for high-temperature applications are specifically designed to withstand high temperatures without losing their mechanical properties. These materials are often used in applications such as automotive, aerospace, and electronics industries. Some examples of plastics for high-temperature applications include polyimide (PI), polyetheretherketone (PEEK), and polybenzimidazole (PBI).

In addition to their unique properties, technical plastics and thermoplastics are highly versatile and can be molded into various shapes and sizes to meet specific requirements. They are also lightweight and offer excellent resistance to wear, corrosion, and impact. As a result, they are widely used in industries such as automotive, aerospace, electronics, construction, and medical.