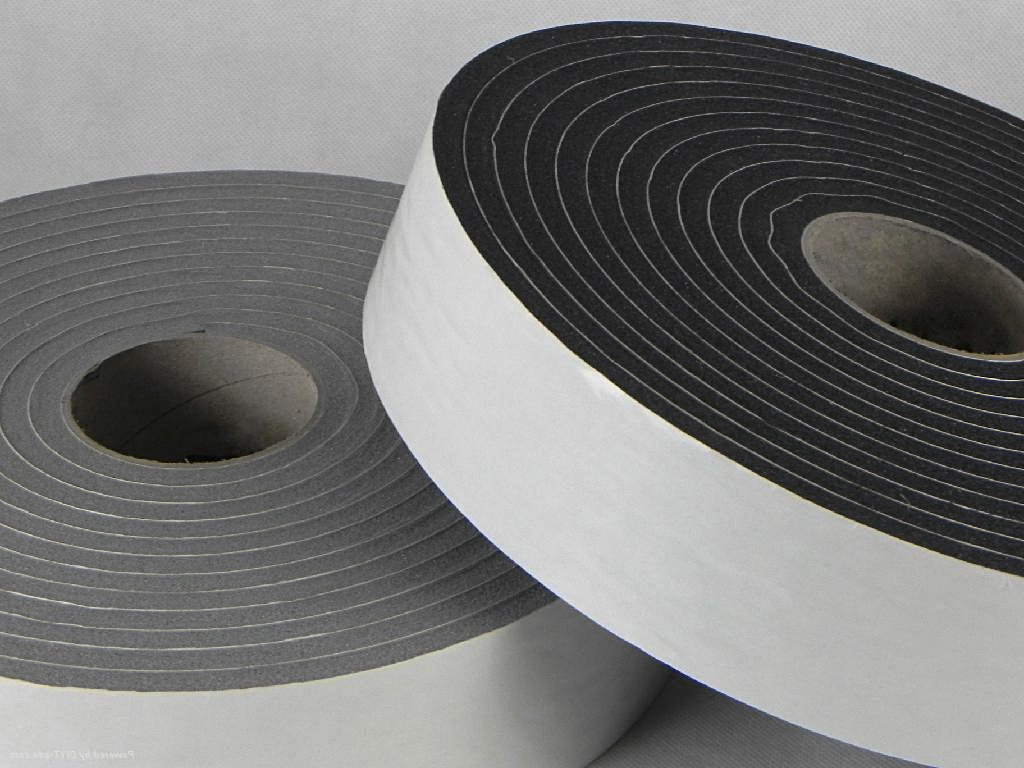

Vinylcell – Foam PVC

Vinylcell is a high-quality material available in rolls. It is used for various industrial applications, including thermal and sound insulation, as well as vibration damping. With its resistance to atmospheric influences, oils, solvents, and acids, it is ideal for use in conditions that require long-term performance and high resistance to external factors.

Material Structure and Technical Characteristics

-

- Material: Foam PVC with excellent flexibility that allows it to return to its original shape.

- Self-extinguishing: It has a Class 1 self-extinguishing property, ensuring high safety standards in industrial environments.

- Color: Standard white, but customization is possible according to requirements.

- Density: Available in various densities – 100/120/150/200 kg/m³, allowing customization for specific user needs.

- Temperature Resistance: Resistant to temperature changes ranging from -50 to +70°C.

- Resistance: Optimal resistance to atmospheric agents, oils, alkalis, and acids makes this material suitable for use in harsh conditions.

Dimensions and Processing

- Rolls: Width 1400/1000 mm, length 10/20/30/60 m, which allows adjustment to different industrial requirements.

- Thickness: From 2 to 20 mm, depending on user needs.

- Processing: Water jet cutting allows precise shaping of the material.

- Self-adhesive Profiles: Foam PVC is also available in a self-adhesive version for easier installation.

Applications

Foam PVC offers a wide range of applications, making it indispensable in many industrial sectors:

-

- Thermal Insulation: Used to prevent condensation, protect systems from moisture, and reduce energy losses.

- Sound Insulation: An excellent material for noise reduction in industrial and commercial buildings.

- Vibration Damping: Efficient as a base plate for reducing vibrations in industrial plants, including machinery and equipment.

- Seals and Washers: Perfect for perforated waterproof seals between windows or other elements, as well as washers for dust and noise protection.

Why Choose Foam PVC?

-

- Resistance to External Factors: Optimal resistance to atmospheric conditions ensures long-lasting performance and durability even in the presence of oils, solvents, and acids.

- Flexibility: Due to its flexibility, foam PVC quickly adapts to shape changes, ensuring high efficiency in applications.

- High Safety: With a Class 1 self-extinguishing property, it meets high safety standards, making it suitable for industrial and commercial applications.