Conveyor belts with side and cross barriers

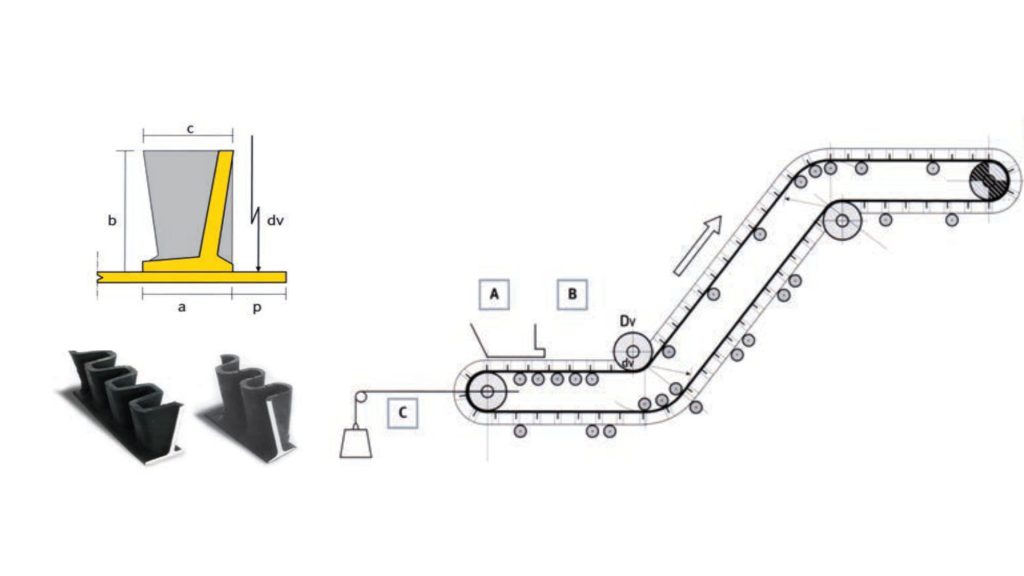

To prevent material from spilling during transport, either on conveyors with a uniform (0 to 90°) or variable incline, the most optimal solution is conveyor belts with side (“accordion”) and cross (“ribs”) barriers.

The belts are available in standard widths ranging from 400 to 2000 mm, with lengths according to customer requirements. To properly dimension the belt, it is necessary to determine:

- the width of the belt and the type of belt base

- the height of the corrugated barriers (“accordion”) and their position on the belt

- the type and number of crossbars on the belt.

Side barriers – “accordion”

The side barriers – “accordion” – are made in a corrugated shape with internal reinforcements that give stability to the entire belt. They can be placed in two or more rows, depending on the width of the conveyor.

For use on variable inclines, it is recommended to use side barriers with greater cross stiffness placed 70 to 120 mm from the edge of the belt, while on constant inclines they are placed on the edges.”

Crosswise limiters

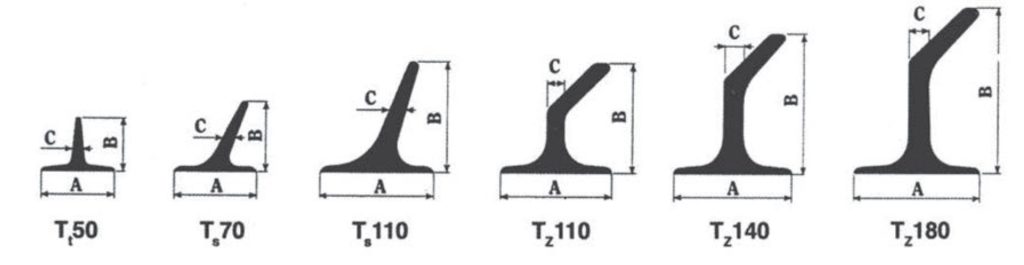

Crosswise limiters – ribs Crosswise limiters can be placed on the belt independently or in combination with side limiters (“accordion”), which correspond proportionally to the height of the ribs (see attached table 1.17.).

They are placed depending on the required capacity of the conveyor, the slope of the conveyor, and the strength of the belt, in a layout of 2 to 5 pieces per linear meter of the belt. There are three types of crosswise limiters available according to their shape: Tt; Ts; Tz