Application

Conveyor belts with barriers (side and cross cleats) represent an optimal solution for preventing material spillage during transport on both flat and inclined conveyors. These barriers, either in the form of side “accordion” cleats or cross “ribs,” enable safe material transfer without loss.

Types

Belts with barriers are available in two types of cleats:

Side Barriers – “Accordion”

Dimensions: Adjustable to conveyor height and material type; available in various sizes according to customer needs.

Shape: The cleats are corrugated and designed with internal reinforcements, giving them high stability.

Function: Provides excellent resistance to deformation and prevents material from spilling over the belt edges.

Installation: Side cleats can be installed in two or more rows, depending on the conveyor width. For variable inclines, cleats with greater transverse stiffness are recommended, placed 70 to 120 mm from the belt edge, while for constant inclines they are positioned at the very edge.

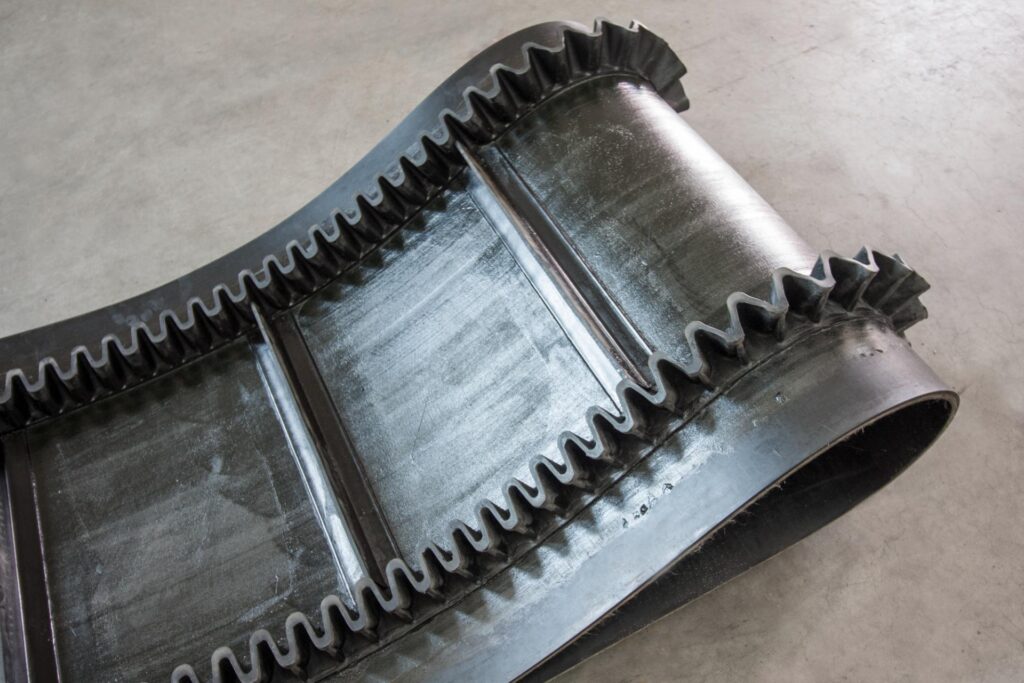

Cross Barriers – “Ribs”

Arrangement: It is recommended to install 2 to 5 cross cleats per linear meter of belt, depending on the transport system requirements.

Installation Method: Cross cleats can be installed independently or in combination with side cleats (“accordion”). The number of cleats depends on the conveyor’s capacity, incline, and belt power.

Function: Cross cleats increase transport capacity and stability on inclines and prevent material spillage.

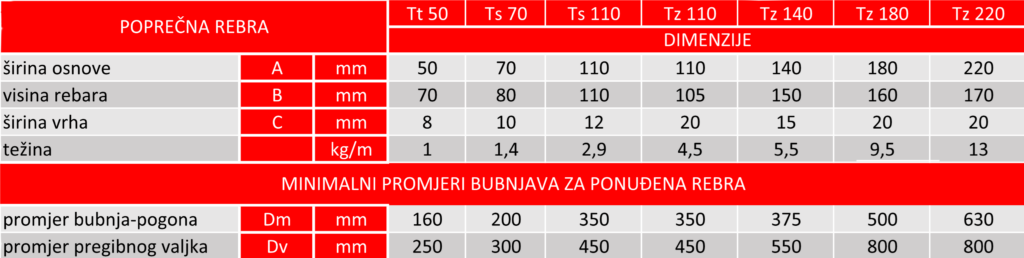

Types of Cross Cleats:

Tt

Ts

Tz

How to Choose the Right Belt with Barriers?

Proper sizing of a conveyor belt with barriers requires considering several key factors:

- Type and Number of Cross Ribs: Determines the conveyor’s capacity and the type of material being transported.

- Belt Width and Base Belt Type: Dimensions must match the conveyor size and industry requirements.

- Height of Corrugated Side Cleats: Height and placement of side “accordions” are crucial for proper belt functionality. Cleats are positioned based on the incline type and material properties.

- Cleat Placement: Correct positioning of side and cross cleats ensures maximum transport efficiency and safety.

Technical Specifications

- Belt Widths: From 400 mm to 2000 mm, with customizable lengths as per customer request.

- Side Cleat Dimensions: Adjustable to conveyor height and material type.

- Cross Cleat Dimensions: Based on conveyor capacity, incline, and industry needs.

Advantages of Conveyor Belts with Barriers

- Transport Optimization: Prevents material spillage on inclines, increasing efficiency and reducing losses.

- High Stability and Resistance: Cleats provide enhanced stability and strength to the belt, ensuring safer transport.

- Customization for Specific Needs: Ability to adjust cleat height, number, and placement allows for optimal solutions for every transport type.

- Versatility: Suitable for various industries including construction, mining, agriculture, and recycling.