High-temperature-resistant conveyor belts are specialized transport belts designed to operate in extreme conditions, ideal for transporting hot materials such as coke, lime, clinker, cast iron, and sintered ore. These belts, with high heat resistance and anti-abrasive properties, ensure reliability, safety, and longevity in industries where exposure to high temperatures is unavoidable.

Key Features of High-Temperature-Resistant Conveyor Belts

- High-resistance rubber cover:

- The belts are equipped with a rubber cover made from a special compound that is resistant to high temperatures and abrasion. This ensures long-lasting performance in industrial conditions with constant contact with hot materials.

- Materials for hot substance transport:

- These belts are specifically designed to transport hot materials such as coke, lime, clinker, cast iron, sintered ore, and other high-temperature materials.

- High-temperature characteristics:

- The belts are designed to withstand extreme temperatures in accordance with DIN 22102-T standards, ensuring optimal performance in industries that require high-efficiency transport systems.

Important Factors When Choosing High-Temperature Conveyor Belts

When selecting high-temperature-resistant conveyor belts, it is important to consider several key factors to ensure the best choice for your application:

- Maximum temperature of the transported material: The belts must be designed to withstand the specific high temperatures of the material being transported.

- Average temperature of the material: Ensure that the belts match the average material temperature to avoid excessive wear.

- Cooling time of the material: Consider how quickly the material cools to ensure the belts are properly designed for optimal performance.

- Size, shape, and abrasiveness of the material: These characteristics affect the choice of belts with appropriate abrasion-resistant rubber and other protective properties.

- Conveyor speed: Adjust the belts to match the conveyor speed to ensure safe and efficient material delivery.

- Transport distance: Longer distances may require belts that are additionally reinforced to endure prolonged operation without loss of performance.

- Size and shape of transported pieces: It is important to select a belt that can handle the specific shapes and sizes of material pieces.

Standard Dimensions and Specifications

High-temperature-resistant conveyor belts are available in various widths and customizable specifications to meet all industrial demands:

- Standard widths: 400, 500, 600, 650, 800, 1000 mm

- Tensile strength: Belts are available according to DIN 22102 standards, ensuring compliance with industry standards for tensile strength.

- Types of protective rubber covers: Depending on the temperature of the transported material and the type of cover, the belts are designed to withstand high temperatures and offer durability in harsh conditions.

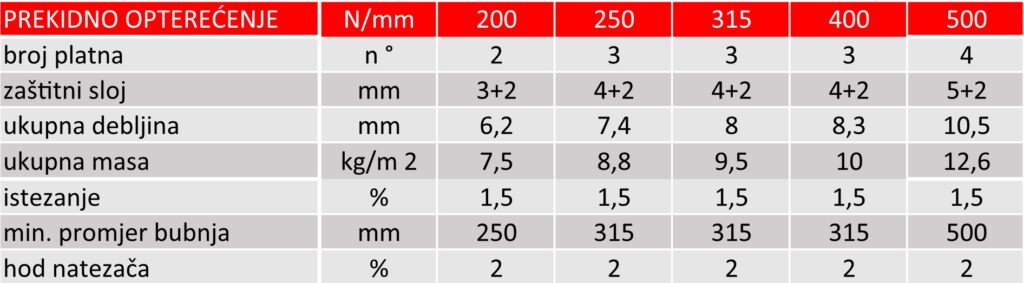

According to tensile strength (in line with DIN 22102 standard)

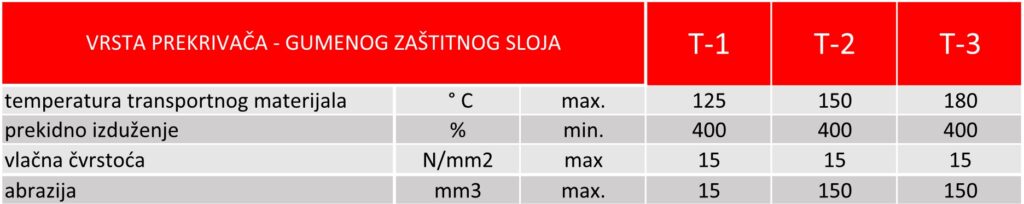

According to the temperature of the transported material (per DIN 22102-T standard) and the type of cover

Advantages of High-Temperature-Resistant Conveyor Belts

- High heat resistance: Belts are optimized for transporting hot materials without losing their characteristics even under extreme conditions.

- Anti-abrasive properties: Rubber layers are abrasion-resistant, ensuring the belt’s longevity even in contact with sharp, hot materials.

- Safety and durability: The belts enable safe transport of heavy and hot materials, reducing the risk of accidents and equipment damage.

- Adaptability to industrial conditions: The belts are designed for use in industries such as cement plants, metallurgy, thermal power plants, and other high-temperature applications.

Contact Us

For all your needs related to transporting hot materials, our company offers high-quality, heat-resistant conveyor belts. Order now and enhance the efficiency of your industrial processes with our reliable transport solutions!