Application

Chevron belts are designed for the transport of powdery, granular, and small lumpy materials on inclines ranging from 20° to 40°, and for operation in harsh weather conditions. They are predominantly used for transporting wood chips, sand and gravel, various minerals, coal and ores, grains, metal shavings, in waste processing and recycling plants, on road construction machinery, and more.

KEY FEATURES OF CHEVRON CONVEYOR BELTS

- Increased carrying capacity on inclines: Unlike standard flat belts that handle slopes up to 20°, Chevron belts allow transportation on inclines up to 40°, thanks to specialized rubber ribs that prevent material from slipping or tipping over.

- High flexibility: The belts can adapt to various types and granularities of materials, from wood chips, sand, gravel, minerals, coal, and ores to grains and metal shavings.

- Vulcanized rubber: The rubber ribs are vulcanized onto the top surface of the belt, ensuring durability and resistance to abrasion.

Standard Dimensions and Specifications

- Chevron conveyor belts are available in various widths and specifications, adaptable to the specific needs of your industrial processes:

- Type of rubber protective cover layer: Belts are available with different types of protective layers that ensure optimal resistance to abrasion, wear, and other external influences.

- Standard widths: 400, 500, 600, 650, 800, 1000, 1200, 1400, 1600 mm

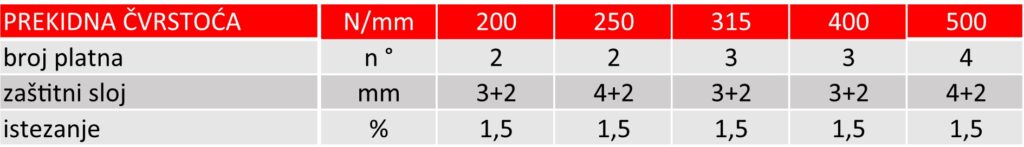

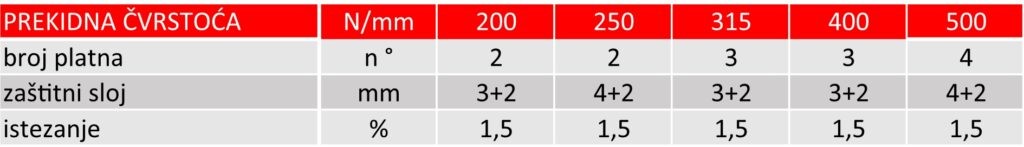

- Breaking load: Belts are designed according to DIN 22102 standards, allowing for high resistance to breaking loads.