Splicing Rubber and PVC Conveyor Belts

Thanks to the expertise and experience of our staff, we are capable of professionally and efficiently responding to customer needs in conveyor belt maintenance. Whether it involves cold or hot vulcanization or the repair of conveyor belts, we guarantee absolute reliability and quality, regardless of where the intervention takes place. In our repair and bonding processes, we use technologically advanced and high-quality materials that achieve long-lasting and effective results, even in harsh environmental conditions.

Before installing the belt, proper calculations of the belt dimensions, transported load, and conveyor characteristics are performed.

The belt dimensions depend on the quantity and characteristics of the transported material, as well as the length and elevation of the conveyor. Transition distances, radius of curvature, and tensioning rates are determined based on an elastic elongation factor of 1.3.

Methods of Splicing

- Cold Vulcanization (Bonding)

- Hot Vulcanization (Vulcanizing Press)

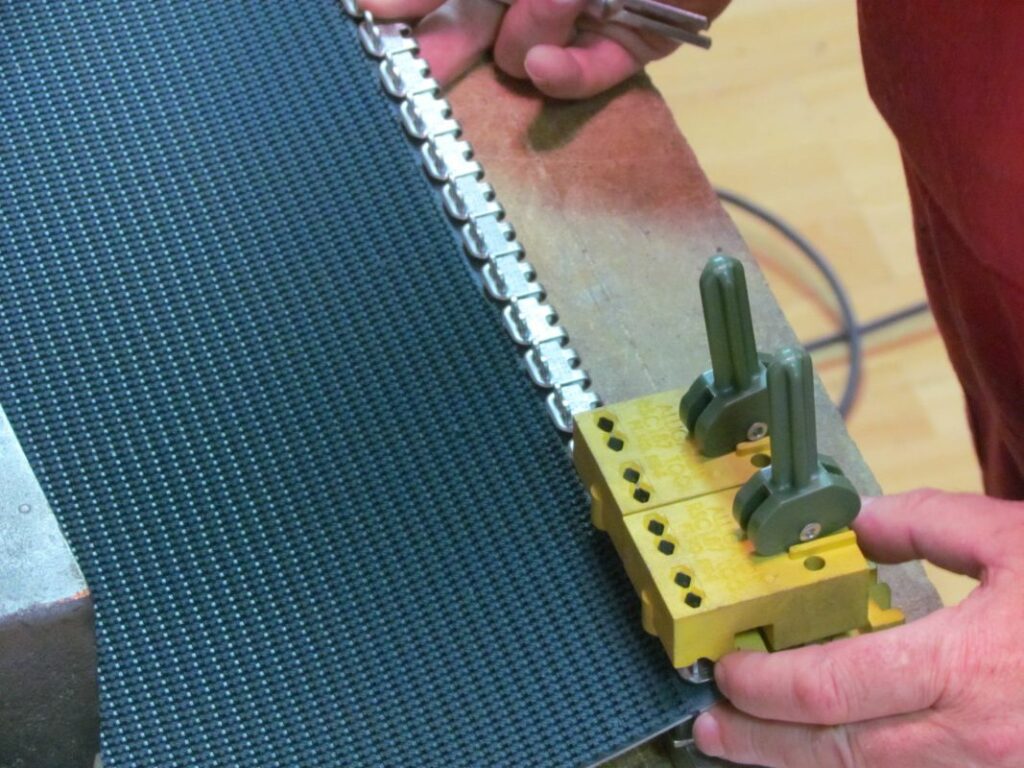

- Mechanical Fasteners

Differences Between Splicing Rubber and PVC Conveyor Belts

Rubber Conveyor Belts (EP fabrics): When splicing rubber conveyor belts, we recommend stepped joints with a beveled cut, where one step (along the length of the belt) is equal to one-third of the belt’s width. The length of a single step is determined based on the number of fabric inserts in the belt and ranges from at least 150 mm to a maximum of 300 mm. The total joint length is calculated as follows:

L = 1/3 b (belt width) + step length x (number of inserts – 1) + 50 mm

If the stepped layers are correctly dimensioned, this splicing method allows for a very secure joint, with properties matching the rest of the belt.

PVC Conveyor Belts: For PVC conveyor belts, the preparation of the ends for bonding is performed using the W Finger technique, which ensures a larger bonding contact area. For more demanding joints (belts with heavy loads), stepped joints with W Finger-treated belt ends are recommended.

Conveyor Drum Lagging

We offer conveyor drum lagging services, using high-quality equipment and tools to ensure the durability and reliability of the rubber coating, as well as the secure bonding between the rubber and the metal drum.