Rubber conveyor belts for sliding surfaces and specialized applications in warehouses and product distribution provide efficient solutions for transporting ceramics, fired bricks, marble, packaging, and other products in bags, packages, boxes, and crates.

Key Features of Rubber Belts for Sliding Surfaces

Low coefficient of friction:

The rubber belt for sliding surfaces offers an exceptionally low coefficient of friction on the bottom (sliding) surface, allowing easy movement of materials with minimal friction.

Resistance to abrasion and atmospheric influences:

The belts are designed for long-lasting use, with high resistance to abrasion, wear, and external atmospheric conditions, ensuring durability and reliability.

Precision:

These belts ensure precise operation, making them ideal for industries where transport accuracy is crucial.

Operating temperature:

The belts have a wide temperature range, operating from -20°C to +80°C, making them suitable for various working conditions.

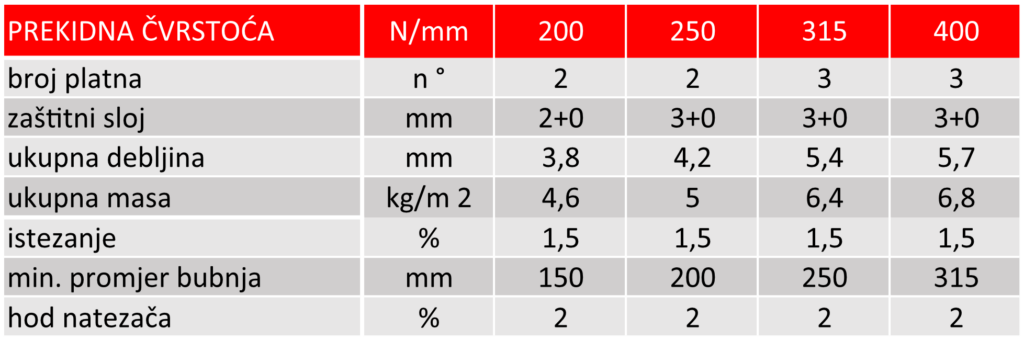

According to tensile strength (according to DIN 22102 standard)

Applications of Rubber Belts for Sliding Surfaces

- Ceramics industry: Suitable for transporting ceramic tiles and other ceramic products.

- Marble industry: Used in marble and stone processing industries for easier movement of heavy and slippery materials.

- Storage and distribution: Ideal for transporting packaged products such as bags, packages, boxes, and crates in warehouses and distribution centers.

Belts with Profiled Surface

Belts with a profiled surface are designed for specific applications in warehouses and product distribution, focusing on transporting products in bags, packages, boxes, and crates.

- Load-bearing layer:

The top layer of the belt has a profiled surface that provides better grip on products and prevents slipping, while the bottom layer has a low coefficient of friction, ensuring easy movement on rollers or flat surfaces. - Storage and distribution:

These belts are perfect for transport in warehouses and distribution centers where sliding of packages is needed but with maximum control over the material.

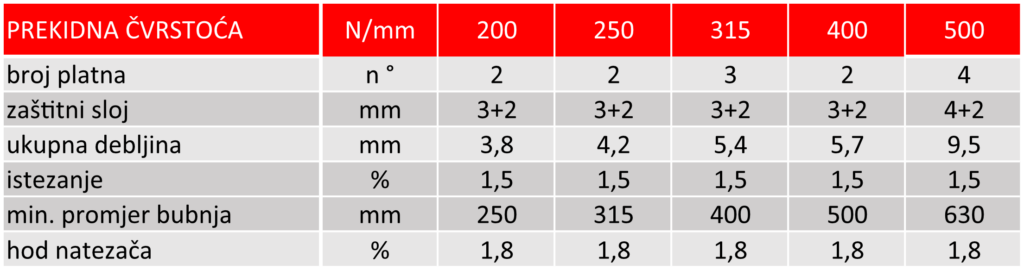

According to tensile strength (according to DIN 22102 standard)

Specifications and Availability

- Tensile strength: Belts are available according to tensile strength in accordance with the DIN 22102 standard.

- Dimensions: Standard widths and lengths of belts are adapted to customer needs.

Advantages of Rubber Belts for Sliding Surfaces

- Reduced friction: Low coefficient of friction allows easy movement of materials with minimal system strain.

- High durability: Resistance to abrasion and atmospheric influences guarantees long service life and reduces maintenance costs.

- Adaptability: Possibility of customization according to specific application requirements, including profiled surfaces for better grip.

Contact Us

For an efficient solution in storage and product distribution, as well as transport on sliding surfaces, rubber belts with profiled layers and low friction coefficient are the perfect choice. Order now and optimize your transport system!